Key to SMT parts and SMT equipment MARKet

Four key elements SMT components

Generally, solder cannot provide high-quality mechanICal support Deep seam strength SMT ink cartridge is much better than surface assembly Usually, this is because the SMT ink cartridge is hit; However, because the die is inserted with a through hole, it provides mechanical support support. Generally, thermal shock during initial welding, red temperature loop during operation, thermal stretching force, torsion force and lead metal are common points of connectors

SMT connector design has four key elements: lead structure, molding compound, mechanical support and lead metal.

(1) Moulding plastic. Traditional thermoplastic materials have low melting point and are not suitable for surface assembly and reflow welding processes. High temperature thermoplasticity data is appropriate, but its high melting point increases processing difficulty and cost. Gull wings and J-pins can be used. However, since the J-pin structure will bend the wire under the main body of the component, it is difficult to visually inspect such connection points. At present, only a few types of connectors use this structure.

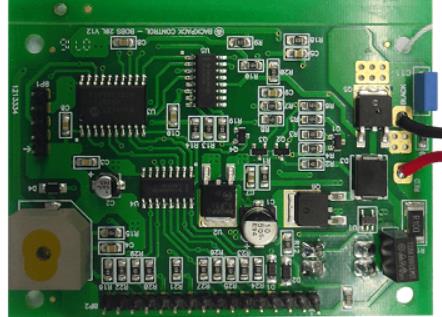

Circuit board

(2) Mechanical support. Except for a few cases, SMT connectors should not only rely on welding as the only mechanical support method, but also use various shaft auxiliary support methods. The connector can be instalLED on the circuit board through riveting, crimping, winding or threaded connection.

(3) Lead structure. The important feature of SMT connector is its flexibility. Obviously, the flexible wire can not only compensate the thermal expansion coefficient between the connector and the circuit board, but also buffer the insertion stress.

(4) Lead metal. In order to ensure sufficient welding strength, the plated metal of connector wire must have high weldability. Poor weldability will not only cause problems in the production process, but also reduce the welding strength. Eutectic tin lead coating provides higher solderability, while other coatings have SIMilar effects.

surface mount equipment market will reach 4.6 billion US dollars

PR Newswire PR Newswire/San Francisco, on May 10, 2021, GIA, the world's leading market research company, released a new market research report today, entitled "The Global Market Trajectory of Surface Mount Technology (SMT patch) Equipment". And Google Analytics. The report puts forward new views on the opportunities and challenges of great changes in the market after the 2019 coronavirus disease.

By 2027, the global SMT equipment market will reach 4.5 billion US dollars

In the 2019 coronavirus disease crisis, it is estimated that the global surface mount technology (SMT) equipment market in 2020 will reach US $3 billion by 2027, with a scale of US $4.5 billion, 6.2% higher than the 2020 analysis cycle shown by the compound annual growth rate from 2027 to 2027. High speed placement equipment is one of the market segments analyzed in the report, which is expected to grow at a compound annual growth rate of 7%, reaching a market size of about $2 billion before the end of the analysis period. After an early analysis of the business impact of the epidEMIc and the economic crisis caused by it, it is estimated that the medium speed installation equipment industry will grow at a compound annual growth rate of 5.8% in the next seven years.

The US market is estimated to be US $30.23 billion, while the Asia Pacific region is expected to grow at a compound annual growth rate of 6.5%

It is estimated that the surface mount technology (SMT) equipment in the US market in the Asia Pacific region will reach 30.23 billion US dollars in 2020, which is expected to reach the expected market size. During the 2020 analysis period, the subsequent compound year of US $1 billion is 6.5%. From 2027 to 2027, the growth rate of markets in other famous regions will be Japan. From 2020 to 2027, the compound annual growth rates of China and Europe will be 4.9%, 7.2% and 3.9% respectively.

The compound annual growth rate of low-speed placement equipment industry will reach 4.8%

In the field of global low-speed placement equipment, the United States, Japan, China and the Asia Pacific region will drive the compound annual growth rate of the industry to about 4%. 8% In 2020, the total market size of these regional markets will be 326.5 million U.S. dollars, which is expected to reach 457.1 million U.S. dollars at the end of the analysis period China is still one of the fastest growing countries in the world. The SMT market in this region is expected to reach 307. By 2027, it will reach 9 million US dollars

The above is the explanation given by the editor of PCB circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High Frequency Circuit Board and SMT chip are waiting for your presence again.