Job definition and work content of SMT engineer

Full time SMT (Surface Mount Technology) process, from material preparation, shelving, to equipment operation setting, maintenance, etc.

prerequisites

With computer science and engineering related background, it can be combined with the professional technology of electronIC parts such as surface adhesion technology (SMT). In addition to professional skills, the team cooperation model needs to be able to bring out good interactive communICation and coordination; Careful attitude can reduce the occurrence of errors and improve work efficiency when facing the machine inspection and component inspection.

job content

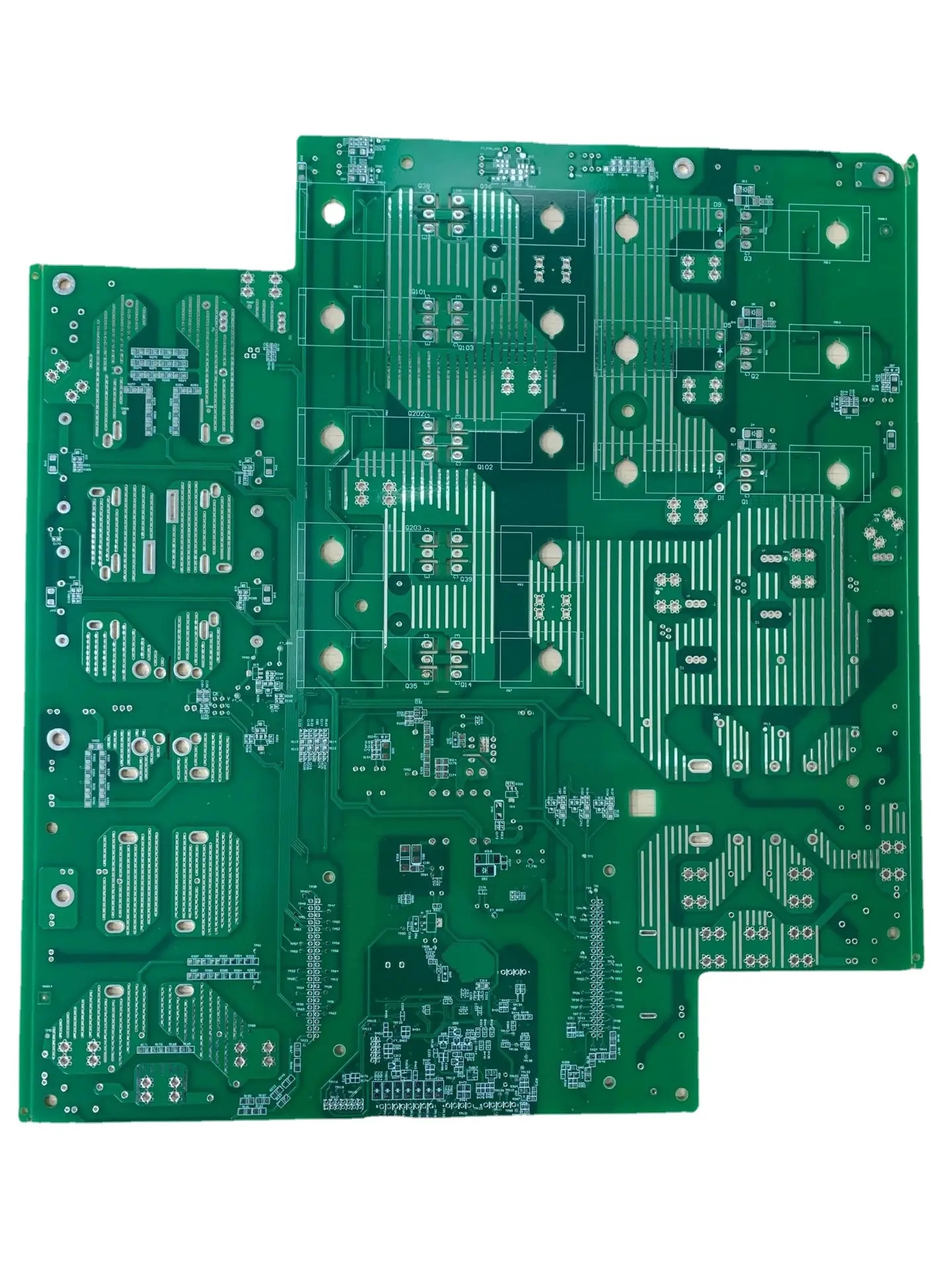

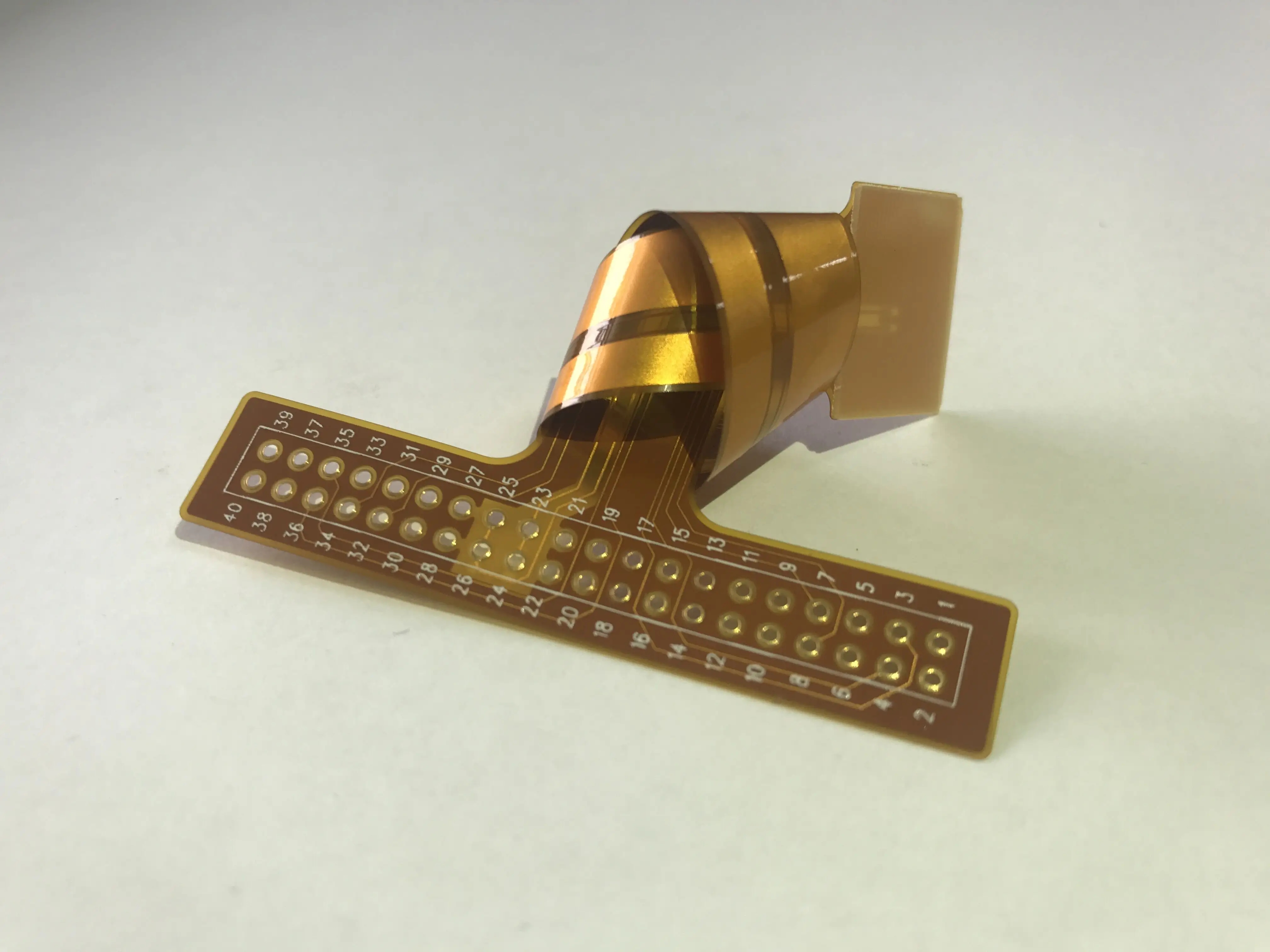

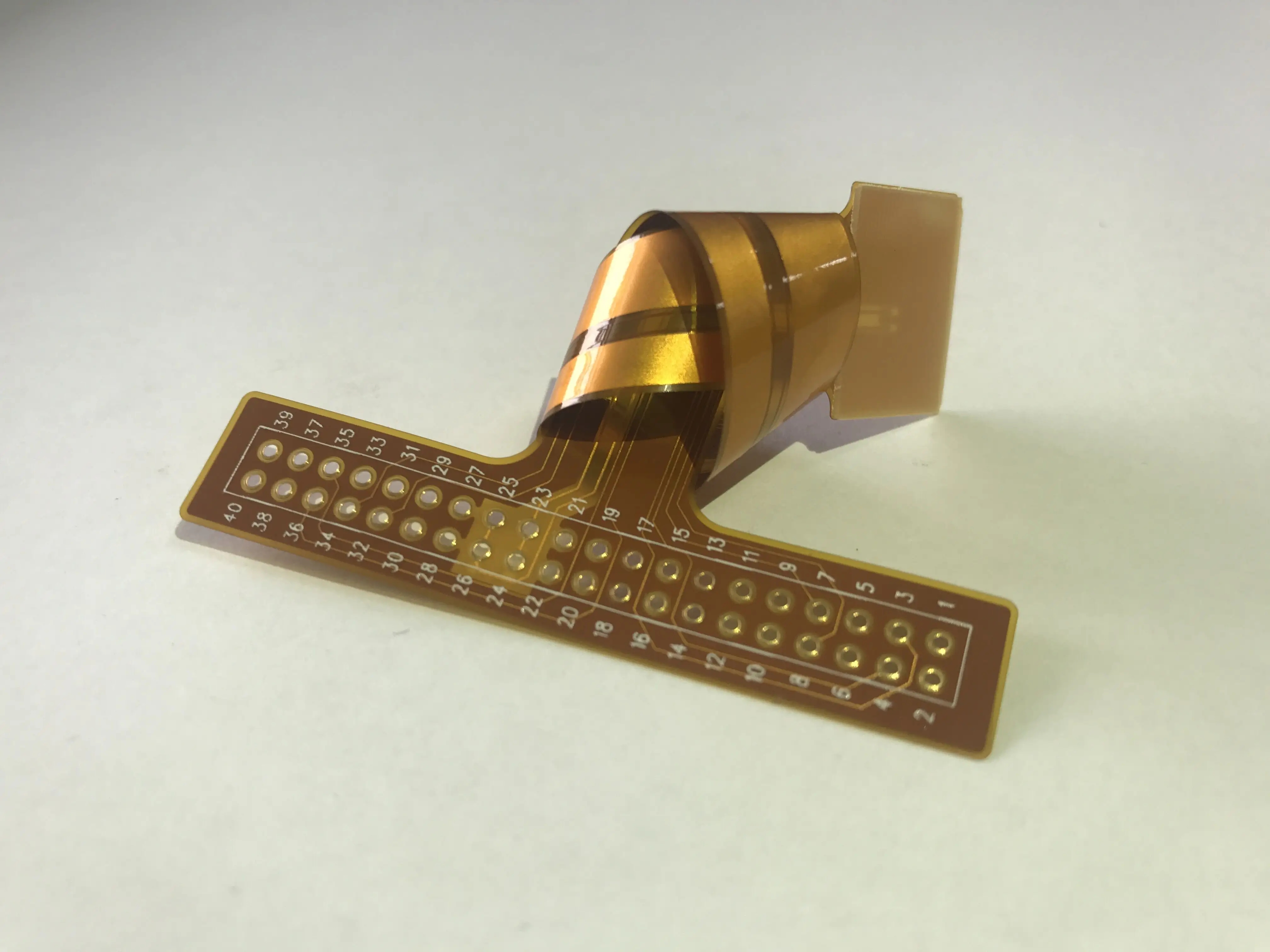

Be responsible for basic technical operations such as SMT machine equipment and solder paste printing, so that electronIC components (such as capacitors, transistors, integrated circuits, etc.) can be completely instalLED on the Printed Circuit Board (PCB) or the flexible printed circuit board (FPCB), check whether the electronic components have abnormal adhesion, and then perform corrective actions. Maintain the machine and other equipment, and check whether the substrate parts have short circuit If problems such as missing parts and reverse direction occur and are solved, check whether the parts are correct according to the samples and the Bill of Material, analyze the problems arising in the process, and propose suggestions for eliminating errors. It is also SMT engineer's responsibility to fill in reports, prepare SMT operation instructions, and research new manufacturing processes.

The certificate of computer hardware decoration technician to improve their own skills. In the future, SMT chip processing engineers can develop into SIMilar positions such as process engineers and electronic engineers. On the contrary, if we continue to deepen the field of SMT, we will have the opportunity to advance to the positions of management engineer, senior SMT engineer, SMT deputy chief engineer, SMT chief engineer, etc.

In the computer and consumer electronics related industries, SMT engineers should control and manage the manufacturing processes in this area, establish standards, introduce and evaluate new manufacturing processes, new materials and equipment, and regularly maintain equipment. They must also be responsible for project planning, making briefings, and communicating their needs with customers.

In the field of electronic components, SMT engineers should be responsible for the maintenance of printed circuit board assembly (PCBA) products, the detection of circuit signals of PCBA, the design of SMT manufacturing process, and the control of SMT progress. SMT equipment should be regularly maintained, and maintenance activities should be carried out. They should also have the ability to plan projects and communicate and coordinate with customers.

SMT engineers have a great chance of being sent abroad. If they want to learn more sophisticated technology, large-scale companies will take more orders for laptops. The return on investment of SMT engineers is not high, but their advantage is that they can control the speed and quality. Sometimes they even need to stand all day long. The main task of SMT is to control quality control, and their feet will become numb after standing for a day. It is SMT's responsibility to ensure the success of adhesion.

Therefore, we should know how to be flexible in work control, so that we can achieve fast and have good quality. SMT is efficient, and customers are in a hurry for goods. Our work belongs to the second half. In order to catch up with the shipment, we often need to come down and work overtime. However, because the factories are moved to the mainland, the competition of SMT in Taiwan is very fierce.

FAQ

Q: What do SMT engineers mainly do?

A: When the product is ready to be printed, it will first be sent to the SMT factory for printing, and all parts on the motherboard will first fix the parts on the preferred PCB, so it will basically be divided into two steps, first SMD and then DIP. However, the SMT engineer is responsible for the whole process.