How to manage high-density HDI PCB through-hole

design of High Density Interconnected PCB Board

The through-hole used for HDI design uses design rules for effective through-hole management, just as hardware stores need to manage and display various types, measurements, data, lengths, widths, and spacing. Nails, screw installation and PCB design objects (such as through holes) also need to be managed on site, especially in high-density design. Traditional PCB design may only use a few different through-hole, but today's high-density interconnection (HDI) design requires many different types and sizes of through-hole. Each through-hole needs to be managed for proper use to ensure improved plate effICiency and error free manufacturability. This paper will introduce the need of managing high-density through-hole in PCB design and how to realize it.

Factors driving high-density pcb board design

As the demand for SMAll Electronic devices continues to grow, the printed circuit boards that drive these devices must also shrink in order to be instalLED in the devices. At the same time, electronic equipment must add more components and circuits on the circuit board to meet the performance improvement requirements. The decreasing size of PCB components and the increasing number of pins complicate the problem because smaller pins and tighter spacing must be designed. For PCB designers, this is equivalent to a smaller and smaller bag containing more and more things. The traditional circuit board design method soon reached its limit.

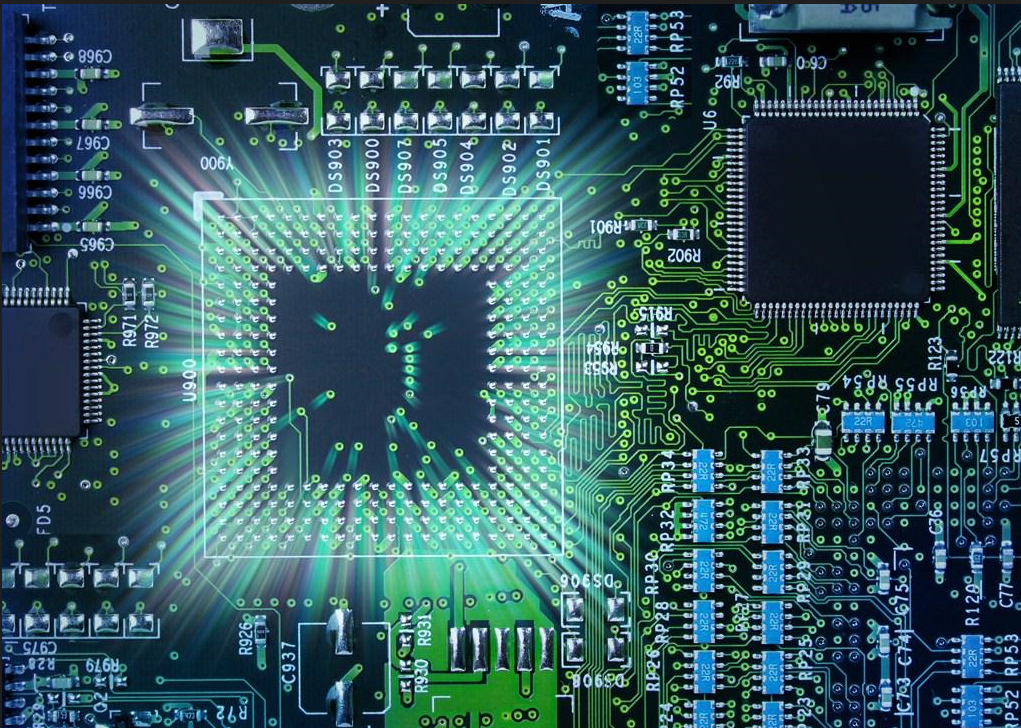

PCB through-hole under microscope

In order to meet the requirement of adding more circuits on a smaller PCB size, a new PCB design method, high-density interconnection, or HDI, has emerged. HDI design adopts more advanced circuit board manufacturing technology, with smaller line width and thinner data, and uses laser drilled blind holes and embedded through-hole or micropore. Because of these high-density characteristics, more circuits can be placed on smaller boards, and provide a viable connection solution for multi pin integrated circuits.

There are several other benefits to using these high-density through-holes:

Cabling channel: because blind hole, embedded through-hole and micro through-hole do not penetrate the layer stack, additional cabling channel is created in the design. By strategically placing these different through holes, designers can route devices with hundreds of pins. If only standard through-hole is used, a device with so many pins will usually block all internal wiring channels.

Signal integrity: Many signals on small electronic equipment also have specific signal integrity requirements, and through holes cannot meet such design requirements. These vias can form antennas, introduce EMI problems, or affect the signal return path of critical networks. The use of blind and embedded vias or micro vias eliminates potential signal integrity problems caused by the use of vias.

To better understand these vias mentioned above, let's look at different types of vias and their applications in high-density design.

The vias list in PCB design tool shows different vias types and configurations

Types and structures of high-density interconnected holes

A through hole is a hole on a circuit board for connecting two or more stacked layers. Typically, through holes transmit signals carried by traces from one layer of the board to corresponding traces on another layer. In order to conduct signals between trace layers, vias are metallized during manufacturing. The through-hole dimensions and pads vary depending on the application. The smaller through-hole is used for signal wiring, while the larger through-hole is used for power and ground wiring, or to help cool overheating devices.

Different types of through-hole on the circuit board

1) Through hole: Through hole is a standard through hole, which has been used for double-sided printed circuit boards since its first introduction. Machine drill and plate the entire circuit board. However, depending on the aspect ratio of the bit diameter to the plate thickness, there is a limit to the hole diameter that can be drilled by the mechanical bit. Generally speaking, the diameter of through hole shall not be less than 0.15 mm.

2) Blind through-hole: Like the through-hole, these through-holes are also drilled by mechanical pipes, but with the addition of manufacturing steps, only part of the circuit boards are drilled from the surface. Blind through-hole is also limited by drilling size; However, depending on which side of the board, we can wire above or below the blind hole.

3) Embedded through-hole: Like blind through-hole, embedded through-hole is also a mechanical drilling, but it starts and ends at the inner layer of the circuit board rather than the surface. Due to the need to be embedded in the layer stack, such through-hole requires additional manufacturing steps.

4) Micropore: the through-hole is ablated by laser, and its diameter is smaller than the 0.15mm limit of the mechanical drill. Since the through holes only span two adjacent layers of the plate, their aspect ratio makes the holes available for electroplating much smaller. Microholes can also be placed on the surface or inside of the circuit board. Microholes are usually filled and plated, and are basically hidden. They can be placed in surface mount assembly solder balls of components such as ball grid arrays (BGA). Due to the small aperture, the bonding pad required for micro holes is much smaller than that for ordinary through-hole, about 0.300mm.

Typical micropores with high-density design

According to the design requirements, the above different types of through-hole can be included to work together. For example, micropores can be stacked with other micropores or embedded vias. These through holes can also be staggered. As previously described, micro holes can be placed in the pad of the leads of the surface mount assembly. By eliminating the traditional trace from the surface mount pad to the fan out through-hole, the problem of routing congestion is further alleviated. These different types of through-hole can be used in HDI designs. Next, let's see how PCB designers can effectively manage the use of vias.

High Density Through Hole Management in PCB Design CAD Tool

Although only several types of through-hole can be used for PCB design, there are many ways to create different sizes and shapes The through-hole used for power and ground connection is usually larger than the through-hole used for conventional wiring, except for the through-hole placed at the bottom of large BGA components with hundreds of pins In addition to BGA pads, micro holes may be required in surface mount pads for these purposes Larger components will benefit from the use of micropores, which are not suitable for traditional surface mounted components with fewer pins; Standard through holes are recommended for this wiring These vias are smaller than power and ground vias and larger for heat dissipation In addition, blind holes and embedded holes of various sizes can be used Obviously, in HDI design, it is easy to be overwhelmed by the many different through-holes required to meet all design requirements Designers can track some of these through-holes. With the increase of through-hole size, it is increasingly difficult to manage through-hole The designer must not only manage all these through holes, but depending on the area of the circuit board, the same network can use different through holes For example, the clock signal can be led out of the BGA pin through the micro hole in the SMT pad, but then returned to the embedded via on the next section of the track But for this mesh, do not use the traditional through-hole, because the additional barrel wall may be on the PCB