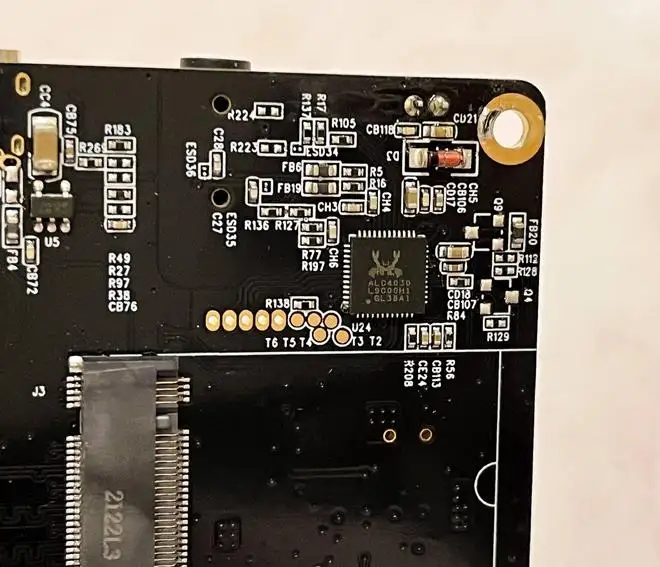

Summary of aging test items of pcb factory

Summary of aging test items explained by circuit board manufacturer

Each function or several functions of electronIC products can be targeted with an aging test item. The aging test is to test the aging age and compression resistance of PCBA after processing and before the launch of electronic products by SIMulating the product use environment. Next, we will introduce the six most common aging test items.

1. Light aging test

Including: Xenon arc lamp aging, UV lamp aging, carbon arc lamp aging

Light aging is the main aging damage to outdoor materials, and indoor materials will also be subject to light aging to a certain extent. The three main lamp sources for simulating light aging have their own advantages. The carbon arc lamp was first invented and used. The measurement system was established earlier. Many Japanese standards and fiber material standards use carbon arc lamps. However, due to the high price and unstable performance of carbon arc lamps (lamps need to be replaced after 90 hours of use), they have been gradually replaced by xenon arc lamps and ultraviolet lamps. Xenon lamp has great advantages in simulating natural light, and its price is relatively low, which is suitable for most products. The ultraviolet lamp produces light below 400nm, which can better accelerate the destruction of materials by ultraviolet rays in simulated natural light. The acceleration factor is higher than that of xenon lamp, and the stability of light source is also better than that of xenon lamp, but it is easy to damage the output of non natural light.

Main application scope: outdoor and indoor rubber and plastic, paint, ink products, communication, electrical and other equipment casings, auto parts, motorcycle accessories.

2. Thermal aging test

The thermal aging box has the program function, which can set the temperature change through the program, and is suitable for the needs of thermal aging of various products.

Main application scope: heat aging test of various products, such as PCB boards, insulating rubber in electrical appliances, long-life products (such as sheathing materials for cable stayed bridges, with a service life of more than 20 years), etc., to investigate the change of materials with the use of time, product performance, and the reliability of product use.

3. Damp heat aging test

The change curve of humidity and temperature can be set according to different product standards and enterprise standards, which is suitable for various complex damp heat aging tests. During the use of the product, it is easy to be affected by both temperature and humidity. For some water sensitive materials, such as PET, PBT, etc., wet heat aging test is required to assess whether they are suitable for long-term use in a humid environment.

4. Salt fog aging test

It is an environmental test that mainly uses artificial simulated salt spray environment conditions created by salt spray test equipment to assess the corrosion resistance of products or metal materials. It is divided into two categories, one is natural environmental exposure test, the other is artificial accelerated simulated salt spray environmental test. The artificial simulated salt spray environment test is to use a kind of test equipment with a certain volume space - salt spray test chamber, and use manual methods in its volume space to create a salt spray environment to assess the quality of salt spray corrosion resistance of products. Compared with the natural environment, the salt concentration of chloride in the salt spray environment can be several times or dozens of times of the salt spray content in the general natural environment, which greatly improves the corrosion rate. The time for obtaining results from the salt spray test of products is also greatly shortened. If a product sample is tested in a natural exposure environment, it may take 1 year for it to corrode, while if it is tested in a simulated salt spray environment, similar results can be obtained in only 24 hours.

Main applicable products: various coatings, such as building exterior wall coatings, marine coatings, container coatings, and various coatings.

5. Ozone aging test

Mainly investigate the ozone resistance of rubber (rubber contains a large number of double bonds, which is vulnerable to ozone attack, especially when it is used dynamically or stretched, ozone damage to rubber is more serious), and also investigate the ozone resistance of TPU, EPDM and other new elastomers.

6. High and low temperature cycle test

The test can be carried out according to the relevant test methods of high and low temperature cycles and freeze-thaw cycles in different product standards. It is mainly used for testing architectural coatings and equipment used in special environments.

The circuit board manufacturer explained the summary of aging test items.