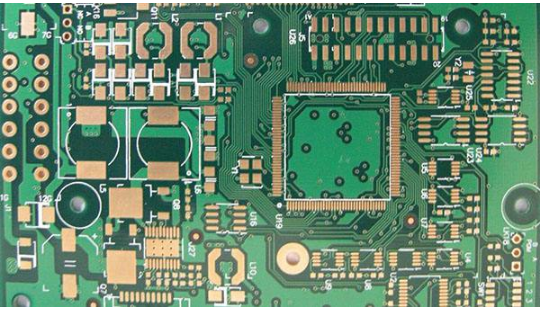

Many companies let PCB hardware engineers to carry out PCB design and program development. In addition to these, hardware engineers need to do more professional work, whICh will certainly extend the time for PCB products to MARKet. And now, with the development of high-speed digital electronic technology, the requirements for high-speed PCB design are also higher: signal integrity SIMulation analysis, timing analysis, single board and whole machine EMC/EMI, etc; In addition, the design density of the single board is getting higher and higher, and the relevant design software must be mastered. These works are serialized, greatly extending the time for product development and marketing. In the fierce market competition, the core competitiveness is an important part of a company's survival. The key to the success of an enterprise is to strengthen its core competitiveness, focus on the best part of its work, and outsource other relevant peripheral parts to partners. Such parallel work is conducive to the timely launch of products, as well as professional assurance of products or design solutions.

So what information does the outsourcing company need to start PCB design when outsourcing PCB design

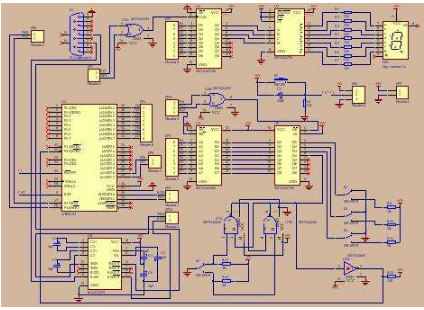

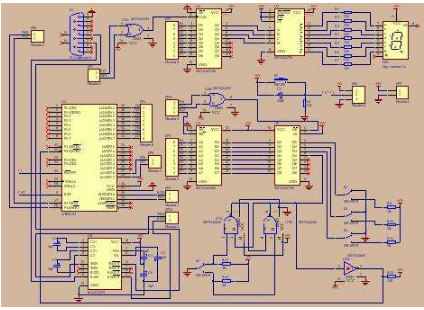

1. Schematic diagram of the final software version

Why the software version? Because PCB design engineers need to refer to the schematic diagram for modular layout in the design process; The current size can be obtained from the schematic diagram, so the PCB designer can improve the PCB design quality greatly after having the schematic diagram.

2. component packaging (specification)

Component packaging refers to the actual size and shape of components in PCB. Because each company has different packaging library specifications, the design company will ask to provide packaging library files before the design starts. If the device is newly added but not packaged, the design company will provide the correct datasheet, and the design company can create packaging according to the Datasheet.

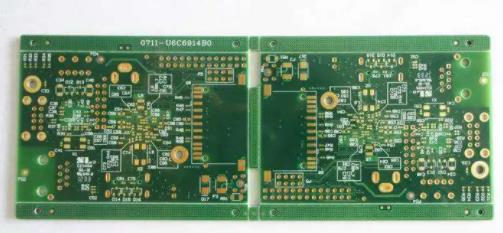

3. Structural drawing of board

The so-calLED board sub structure drawing is also the board frame size drawing. With this size drawing, the engineers of the design company can arrange the wiring according to the board size. Of course, it also involves the location of fixed components. Therefore, the design company needs to be informed of the fixed components before the design, which is convenient for the design company to arrange. The size of the board and frame is one of the factors that have a great impact on the design. The change of the board and frame will cause a great amount of PCB design change. Therefore, before the design, the structure should not be modified as much as possible. The design company will charge the change fee as the case may be for the workload of PCB change.

4. Design requirements

Design requirements refer to the basic characteristics of Board Design and special design requirements, such as the number of PCB layers, the minimum line width and aperture, and special rules for routing. With these requirements, designers consider these factors at the beginning of design. The design can be completed more smoothly in the later stage.

Therefore, if outsourcing can accurately provide the contents mentioned in the above four points, it will be very easy for outsourcing companies to design PCB in the future. Although PCB design is mainly done by PCB engineers, PCB design is a process of cooperation between hardware engineers and PCB design engineers. Therefore, in the design process, it is impossible to avoid the need for hardware engineers to change the schematic diagram. At this time, hardware engineers need not complain. This is also a necessary process for good PCB design.