Types of patch adhesives and SMT pastes

Patch adhesive type: during SMT patch processing, thermosetting patch adhesive is usually used to paste components onto PCB The main materials used are epoxy resin, polypropylene, propionIC acid nitrile and polyester Common repair adhesives include epoxy repair adhesive and acrylic repair adhesive

1. Epoxy resin patch adhesive and epoxy resin patch adhesive are the most commonly used patch adhesive in SMT patch processing. The main components are epoxy resin, curing agent, filler and other additives. The curing method of epoxy resin repair adhesive is mainly thermal curing. Epoxy resin is a thermosetting adhesive with high viscosity, which can be made into liquid, paste, film and powder. The thermosetting adhesive will not soften after curing and will not reestablish the bonding connection. Thermosetting data can be divided into one component and two components.

2. Acrylic repair adhesive. Acrylic patch adhesive is another main patch adhesive commonly used in SMT patch processing. Its components mainly include acrylic resin, light curing agent and filler, and it is a light curing patch adhesive. Acrylic resins are also thermosetting adhesives and are commonly used as one component systems. It is characterized by stable performance, short curing time, sufficient curing, easy control of process conditions, room temperature storage conditions and dark storage, up to one year, single bond strength and power efficiency are inferior to those of epoxy resin type.

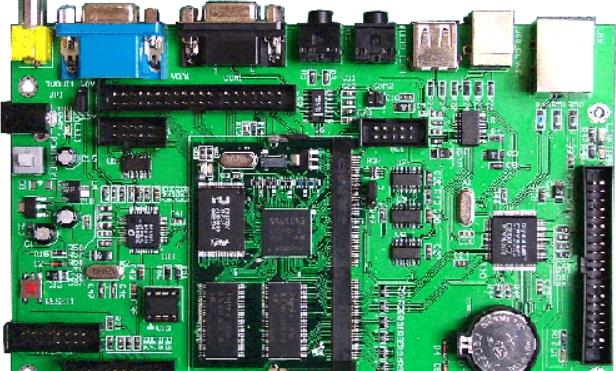

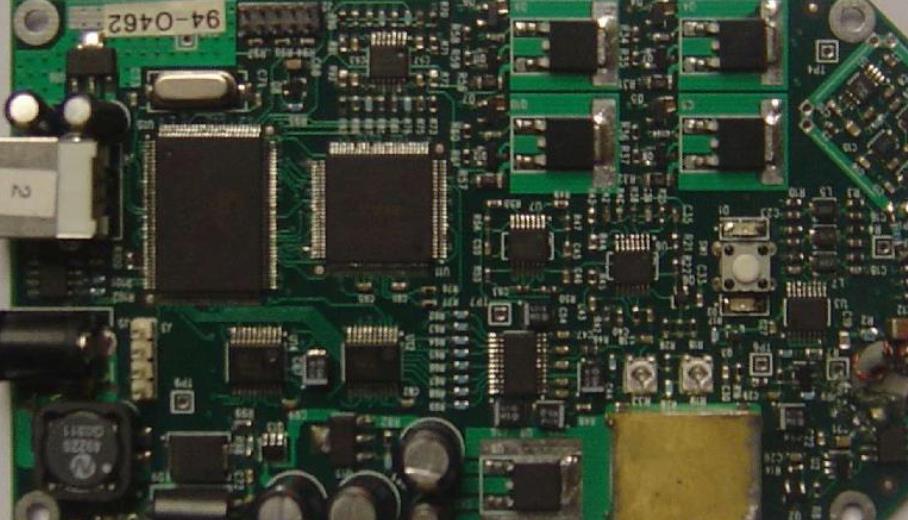

Circuit board

solidification. The curing methods of the adhesive include heat curing and light curing. Light and heat dual curing and ultrasonic curing, among which light curing is rarely used alone. Ultrasonic scratches are usually used for adhesives that use sealing curing agents. The most commonly used curing methods in the processing of Smt patch mainly include thermal curing and UV/thermal curing.

1. Thermal curing. Thermal curing usually has two forms: oven intermittent thermal curing and infrared oven continuous thermal curing.

2. UV/heat curing. The UV/thermal curing system uses UV irradiation and heating methods to rapidly cure adhesives on a continuous production line.

Selection of SMT adhesive: How to select the appropriate SMT adhesive to ensure SMT production is the most concerned problem for electronic product technicians It is usually used to list the performance indicators of the patch adhesive, refer to the table, and follow the table in each item to test and compare the selected patch adhesive and select the excellent varieties

How to print SMT solder paste

Due to the metallurgical reaction in the welding process, the tin in the solder and the base metal form an alloy, while the lead hardly participates in the reaction below 300 ° C. However, after adding lead to tin, excellent properties that both tin and lead do not have can be obtained, which are shown in the following aspects.

(1) Lower the melting point for welding. The melting point of tin is 231.9 ℃ and that of lead is 327.4 ℃. Both are 183 ℃ higher than the melting temperature of solder. If tin and lead alloys are mixed, the melting point of the alloy is lower than that of the two metals, and the welding process is easy to operate.

(2) Improve mechanical efficiency. Due to the addition of lead, the mechanical efficiency (tensile strength and shear strength) of tin lead metal is more than twice that of its single component.

(3) Reduce surface tension. The surface tension of tin lead alloy is lower than that of pure tin, which is beneficial to the wetting of solder on the surface of welding metal.

(4) Antioxidants. Adding lead to tin can improve the oxidation resistance of solder and reduce the amount of oxidation.