Dispensing and Welding Technology of SMT Dispensing Machine

Distribution method of distributor in production and processing SMT patch

In the production and processing of SMT patches in electronIC processing plants, some relatively special electronIC components can not only use the common solder paste welding process This is because of their particularity The common solder paste welding process will lead to some problems, affecting their use and life Under normal circumstances, some special processing measures will be taken for the processing of SMT chip components produced in SMT, such as dispensing technology

In SMT chip production and processing, dispensers are generally divided into manual and automatic types, which are different for SMAll batch and mass production. The most important part of the distributor is the distribution head.

According to different distribution pumps, distribution heads can be divided into four types: time pressure type, screw pump type, linear positive displacement pump type, jet pump type, etc. Four types of allocation headers are briefly introduced below.

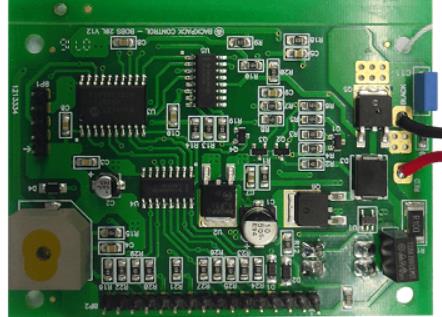

Circuit board

1. Time pressure distribution head.

In the eyes of many people, pneumatic pump has always been the most direct dispensing pipeline in SMT production and processing. It uses the time pressure principle to start the operation by using the controlLED pulse air flow generated by the compressor. The longer the action time of air flow pulse during the operation, the larger the proportion of coating materials pushed out from the needle.

2. Screw pump dispensing head.

The screw pump dispensing head has strong flexibility and is suitable for dispensing various patch adhesives. It is insensitive to the air mixed in the patch adhesive, but sensitive to viscosity changes. Allocation speed also affects the consistency of allocation.

3. Linear positive phase displacement dispensing head.

The linear positive phase shifting head has good glue point consistency when dispensing at high speed. It can dispense large glue points, but the cleaning is complex and sensitive to the air in the patch adhesive.

4. Jet pump type dispensing head.

The jet pump type is a non-contact distribution head with fast distribution speed and is insensitive to PCB warpage and height change. However, the speed of larger glue spots is relatively slow, requiring multiple spraying and complex cleaning.

Three common welding techniques in SMT chip processing

Three common welding technologies in smt chip processing are wave soldering technology, reflow soldering technology and laser reflow soldering technology.

1. Wave soldering technology for smt wafer processing. The wave soldering technology mainly uses SMT wire mesh and adhesive to firmly fix the electronic components on the printed circuit board, and then uses wave soldering equipment to solder the circuit board chip immersed in molten tin. This welding technology can realize the double-sided processing of the chip, which helps to further reduce the volume of electronic products. However, this kind of welding technology has the defect that it is difficult to realize high density SMT assembly processing.

2. Reflow soldering technology for smt wafer processing. The reflow soldering technology is based on the SMT steel mesh of appropriate specification and model. The solder paste is temporarily printed on the electrode pad of the electronic components, so that the electronic components are temporarily set at their respective positions. Then, according to the reflow soldering machine, the solder paste on each lead pin melts and flows again, completely penetrates into the electronic components and circuits on the patch, and is cured again. Reflow soldering technology for SMT processing is SIMple and fast, which is commonly used by SMT wafer processing manufacturers.

3. Laser reflow technology SMT chip processing Laser reflow technology is usually the same as reflow technology The difference is that laser reflow welding uses laser to directly heat the welding position, so that the solder paste melts and flows again When the laser stops irradiating, the solder will condense again to form a stable and reliable welding connection This method is faster and more accurate than the former, and can be regarded as an improved version of reflow technology